CIP Tank Cleaning System uses advanced cleaning technology and equipment to achieve an automated and continuous cleaning process. It can efficiently remove dirt and residues on the surface of the equipment to ensure the hygiene and safety of the production environment. It is easy to operate and maintain, and is an indispensable cleaning solution in modern industrial production.

CIP Tank Cleaning System is suitable for soaking and softening animal skins such as donkey skin, cow skin, deer skin, as well as plant skins, rhizomes and other products, and has a low-cost cleaning function.

It is mainly composed of frame, drum, transmission system, heating system, filtration system, braking system, intelligent control system, circulation system, etc. The equipment is made of 304 / 316 and other materials, which meets the requirements of pharmacy and food. lt has the characteristics of energy saving, large production capacity, soft soaking and good soaking effect.

During operation, the drive gear of the reducer drives the drum body to rotate. The materials in the drum are mixed with water and liquid, and they are constantly turned under the push of the spiral belt. The journey is a dynamic process. Therefore, compared with the traditional way, it greatly shortens the soaking and softening time, and takes into account the role of cleaning at the same time. Variable frequency speed regulation, stable and reliable operation, simple and easy to manage and maintain. The volume can be customized according to user needs. PLC automatic control mode is adopted to realize forward and reverse rotation, low-speed start, quantitative automatic water addition, automatic temperature control, speed setting, time setting, etc. Large diameter material inlet and outlet, convenient for material input and discharge. The equipment has a high degree of automation, and there is no need for personnel intervention in the work, which can greatly reduce the labor cost.

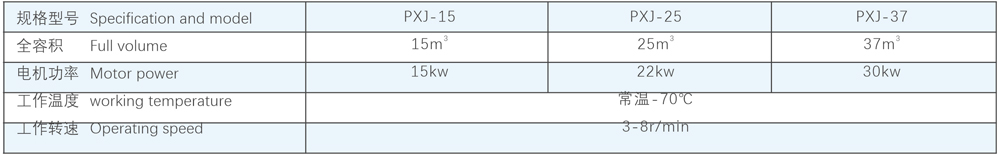

Note: the equipment model can be customized according to user needs!

GET A QUOTE